Welcome to Shandong Sanjin Steel Co., Ltd

WhatsApp:+8615806975270 Email : manager@sdsanjinsteel.com

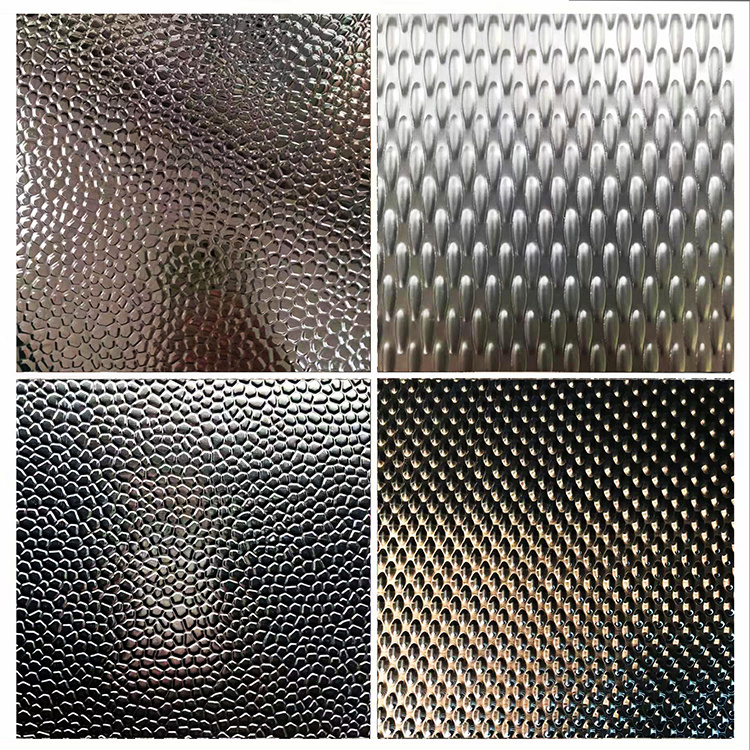

Stainless Steel Checkered Plate /Diamond Plate / Pattern Plate / Embossed Plate

PRODUCT DETAILS

The stainless steel checkered plate is embossed on the stainless steel plate by mechanical equipment, so that the surface of the plate has concave and convex patterns. The stainless steel checkered plate has excellent corrosion resistance and slip resistance. There are 5WL/6WL/2WL/Linen/square/diamond/concave diamond/convex diamond/tile/stone brick/ripple and other specifications. On the basis of the above, new products such as coloring, coating, compounding, nano-sealing, super anti-corrosion, anti-bacterial, and anti-wear stainless steel pattern plates are constantly meeting the needs of human beings for a high-quality life and industry innovation.

Sanjin Steel can produce and supply stainless steel checkered plates in various patterns and styles, and supports customization. Welcome to contact us!

There are two types of stainless steel checkered plates:

One type is rolled by rolling mills when steel mills produce stainless steel. The main thickness of this type of product is about 3-6mm. It is in the state of annealing and pickling after hot rolling. The process is as follows:

Stainless steel billet→black coil rolled by hot continuous rolling mill→hot annealing and pickling line→tempering machine, tension leveler, polishing line→cross-cutting line→hot-rolled stainless steel pattern plate

One side of this type of checkered plate is flat and the other side is patterned. This kind of checkered plate is more commonly used in chemical industry, railway vehicles, platforms and other occasions that require strength.

The second category is the processing enterprises in the market, which buy hot-rolled or cold-rolled stainless steel plates from steel mills, and stamp them through mechanical stamping. This type of product is concave on one side and convex on the other, and is often used for general civil decoration. There are many cold-rolled products of this kind, and most of the 2B/BA cold-rolled stainless steel checkered plates on the market are of this type.

Common standard comparison table for stainless steel checkered plate:

|

ASTM |

EN |

GB |

Cr Ni Mo C Cu Mn |

|

ASTM 304 |

EN1.4301 |

06Cr19Ni10 |

18.2 8.1 - 0.04 - 1.5 |

|

ASTM 316 |

EN1.4401 |

06Cr17Ni12Mo2 |

17.2 10.2 12.1 0.04 - - |

|

ASTM 316L |

EN1.4404 |

022Cr17Ni12Mo2 |

17.2 10.1 2.1 0.02 - 1.5 |

|

ASTM 430 |

EN1.4016 |

10Cr17 |

Add.188.022.6.1345 |

Stainless steel checkered plate grade and its theoretical weight:

|

Grade |

theoretical weight |

Grade |

theoretical weight |

|

lCrl7Mn6Mi5N |

7.93 |

3Crl3 |

7.75 |

|

lCrl8MnBNiSN |

7.93 |

0Crl7Ni12M02 |

7.98 |

|

lCrl7Ni7 |

7.93 |

00Crl7Nil4M02 |

7.98 |

|

1Crl7Ni8 |

7.93 |

0Cr17Ni12M02N |

7.98 |

|

1Crl8Ni9 |

7.93 |

00Crl7Nil2M02N |

7.98 |

|

lCrl8Ni9Si3 |

7.93 |

0CrlSNil2M02Cu2 |

7.98 |

|

OCrl9Ni9 |

7.93 |

00Crl8Nil4M02Cu2 |

7 98 |

|

00Crl9Nil l |

7.93 |

0Crl9Nil3M03 |

7 98 |

|

0Crl9Ni9N |

7.93 |

00Crl9Nil 3M03 |

7 98 |

|

00Crl 8NilON |

7.93 |

0Crl8Nil6M05 |

8 00 |

|

00Crl8Nil2 |

7.93 |

0Crl8Ni11Ti |

7.93 |

|

0Cr23Nil3 |

7.93 |

OCrl8NillNb |

7.98 |

|

0Cr25Ni20 |

7.93 |

0Crl8Nil3Si4 |

7.75 |

|

00Crl7MO |

7.98 |

00crl8M02 |

7.75 |

|

7Crl7 |

7.70 |

00Cr30M02 |

7.64 |

|

0Cr26Ni5M02 |

7.70 |

lCrl5 |

7.70 |

|

lCrl2 |

7.80 |

3Crl6 |

7.70 |

|

0Crl3A1 |

7.7S |

lCrl7 |

7.70 |

|

1Crl3 |

7.7S |

OOCrl7 |

7.70 |

|

OCrl3 |

7.75 |

lCrl7Mo |

7.70 |

|

OOCrl2 |

7.75 |

00Cr27Mo |

7.67 |

|

2Crl3 |

7.75 |

0Crl7N|7Al |

7.93 |

What is super slippery anti-adhesive self-hiding scratch stainless steel checkered plate?

The super-slip anti-adhesive self-hiding scratch stainless steel checkered plate entered China for the first time in August 2010. The main innovative models are: 2, 3, 5, 6, WL series. The point-like protrusions on the surface of the stainless steel plate are 30-40% higher than the slideway efficiency of the ordinary stainless steel plate, especially the 3WL series NANO and SUPER are 40-60% higher than the ordinary plate. The problem of low efficiency of slideways in the machinery and equipment industry is perfectly solved.

Factory Appearance

*What is stainless steel and its features?

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

*How is stainless steel classified?

SS are usually divided into martensitic steels, ferritic steels, austenitic steels, austenitic ferritic (duplex) stainless steels and precipitation hardening stainless steels according to the structure state.

The models of stainless steel can be divided into Cr series (400 series), Cr Ni series (300 series), Cr Mn Ni (200 series) and precipitation hardening series (600 series) according to composition.

Stainless steel plate is an alloy steel with smooth surface, high weldability, corrosion resistance, polishability , heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel according to the structure state.

Austenitic Stainless Steel stainless steel with an austenitic structure at room temperature. Steel contains Cr≈18%, Ni≈8%-25% and C≈0.1%. Steel has high toughness and plasticity, but low strength.

Martensitic Stainless Steel

A steel whose mechanical properties can be adjusted by heat treatment. It has different strength and toughness at different tempering temperatures.

Duplex Stainless Steel

Austenitic and ferrite each account for about half of the structure. When the C content is low, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some steels also contain alloying elements such as Mo, Cu, Si, Nb, Ti, and N. This type of steel has the characteristics of austenitic and ferritic stainless steel

Ferritic Stainless Steel

It contains 15% to 30% chromium and has a body-centered cubic crystal structure. This type of steel generally does not contain nickel, and sometimes contains a small amount of Mo, Ti, Nb and other elements. This type of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance.

Packing and shipping

PACKAGING:

Excellent package: Anti-water paper and plastic film+covered by iron sheet+ strapped with min three strapping strips+fixed on the iron or wooden pallets by strapping strips.

SHIPPING:

We have long-term cooperation with many experienced shipping companies and will find the most suitable mode of transportation for you.

Export standard package, bundled or be required.

The inner size of container is below:

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high)

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high)

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high)

Delivery Details: 7-15 das or according to the order quantity or upon negotiation

Customer conversation

Since its establishment, our company has always adhered to the principle of "quality and progress, integrity and trust".

Application area

*How are different surfaces of stainless steel formed and its usage?

1) Original surface: NO 1. Surfaces subject to heat treatment and pickling after hot rolling. It is generally used for cold rolling materials, industrial tanks, chemical industrial devices, etc.

2) Blunt face: NO 2D. cold rolling and heat treatment and pickling, the material is soft and the surface is silvery white luster, which is used for deep stamping processing, such as automobile components, water pipes, etc.

3) Fog surface: NO 2B. cold rolled, heat treated, pickled, and then finish rolled to make the surface moderately bright. it is widely used, such as tableware, building materials, etc

4) Fine sand: NO 4. It is grinded with 150-180 abrasive belt which is used for bath, decoration materials inside and outside buildings, electrical products, kitchen equipment, food equipment, etc.

5) HAIRLINE: HL. It is with grinding patterns generated by continuous grinding of polishing abrasive belt with proper grain size (subdivided into 150-320). It is mainly used for building decoration, elevators, doors and panels of buildings.

6) Bright surface: BA. It is cold rolled, bright annealed and leveled. Excellent surface gloss and high reflectivity. A mirror like surface, used for home appliances, kitchen equipment, decorative materials, etc.

Stainless steel Plate is a common steel, it has many advantages, such as corrosion resistance, high temperature resistance and so on.

The main uses are:

1. used for welding structural parts: such as oil pipelines, chemical equipment, Marine equipment, etc.;

4. used for the manufacture of medical instruments and food industry utensils and other requirements of non-toxic sanitation or sterile environment of the parts.

2. used for processing all kinds of conventional parts and for stamping die;

3. used as high precision mechanical parts of steel;

7. It is often used in the construction industry to make stair treads and other forms of structural components.

5. It is widely used in the heat treatment process of stress relief annealing before bending.

6. It is used to reduce weight and noise.

11. It can be applied to household appliance industry. The nuclear energy sector. Space and aviation. Electronic and electrical

8. It is widely used in the chemical industry to produce fertilizers and other chemicals.

9. It can be used as a building material for civil construction.

10. It can be used in automobile industry.

Exercise equipment. Household goods. Can replace copper pipe.

field. Medical machinery industry. The shipbuilding industry. Decorative tubing. Furniture. The elevator. Decorative materials.

Aertificate of honor

All products are manufactured according to ASTM standard, JIS standard, DIN standard, BS standard and other standards.

COOPERATIVE PARTNER

FAQ

Q:How do you make our business long-term and good relationship?

Q:What do your factory do regarding quality control?

Q: How long is your delivery time?

Q:how can we guarantee quality?

A:Always a pre-production sample before mass production;Always final Inspection before shipment;

Q:what can you buy from us?

A:Carbon steel, stainless steel, galvanized steel, color coated, PPGI, PPGL, steel structure, etc.

Q.Do you provide custom made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawing.

Q:What are the certifications for your products?

A:We have ISO 9001, MTC, third parties’ inspections are all available such SGS, BV ect.

RELATED PRODUCTS

GET A FREE QUOTE